Superabsorbent Polymer History

Until the 1920s, water absorbing materials were fiber-based products. Choices were tissue paper, cotton, sponge, and fluff pulp. The water absorbent capacity of these types of materials is only up to 11 times their weight and most of it is lost under moderate pressure.

In the early 1960s, the United States Department of Agriculture (USDA) was conducting work on materials to improve water conservation in soils. They developed a resin based on the grafting of acrylonitrile polymer onto the backbone of starch molecules (i.e. starch-grafting). The hydrolyzed product of the hydrolysis of this starch-acrylonitrile co-polymer gave water absorption greater than 400 times its weight. Also, the gel did not release liquid water the way that fiber-based absorbents do.

The polymer came to be known as “Super Slurper”. The USDA gave the technical know-how to several USA companies for further development of the basic technology. A wide range of grafting combinations were attempted including work with acrylic acid, acrylamide and polyvinyl alcohol (PVA).

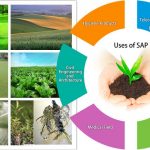

Today’s research has proved the ability of natural materials, e.g. polysaccharides and proteins, to perform super absorbent properties in pure water and saline solution (0.9%wt.) within the same range as synthetic polyacrylates do in current applications. Soy protein/poly(acrylic acid) superabsorbent polymers with good mechanical strength have been prepared. Polyacrylate/polyacrylamide copolymers were originally designed for use in conditions with high electrolyte/mineral content and a need for long term stability including numerous wet/dry cycles. Uses include agricultural and horticultural. With the added strength of the acrylamide monomer, used as medical spill control, wire and cable water blocking.